X-ray technology has become a cornerstone in modern imaging, non-destructive testing (NDT), medical diagnostics, and scientific research. The performance and reliability of X-ray systems depend heavily on the core components that control power and voltage within the system. Among these, the X-ray tube power supply, precise X-ray voltage regulation, and advanced high voltage generators for X-ray play critical roles. These components ensure that imaging systems operate safely, efficiently, and with the precision required for complex applications.

What is an X-Ray Tube Power Supply?

The X-ray tube power supply is the central unit that delivers and regulates the electrical energy required by the X-ray tube. X-ray tubes generate X-rays by accelerating electrons towards a target material at very high voltages, producing radiation as the electrons decelerate. Without a stable and well-controlled power supply, the X-ray tube cannot function correctly, potentially compromising image quality or even damaging the tube.

Key features of modern X-ray tube power supplies include:

- High Stability: Maintaining consistent voltage and current to ensure uniform X-ray output.

- Adjustable Output: Allowing fine-tuning of X-ray intensity based on the imaging requirements.

- Protection Mechanisms: Safeguarding the tube and connected electronics against overcurrent, voltage spikes, or short circuits.

- Compact Design: Enabling integration into portable or space-limited systems without compromising performance.

These features make the X-ray tube power supply indispensable in medical imaging devices, industrial inspection machines, and scientific research equipment.

The Role of X-Ray Voltage in Imaging Systems

X-ray voltage refers to the potential difference applied across the X-ray tube, which accelerates electrons from the cathode to the anode. This voltage directly influences the energy and penetration capability of the X-ray photons produced. Higher X-ray voltage allows the radiation to penetrate denser materials, while lower voltage produces softer X-rays suitable for detailed imaging of softer tissues or thin materials.

The benefits of precise X-ray voltage control include:

-

Consistent Image Quality:

Prevents fluctuations that could blur images or produce inconsistent results.

-

Material Penetration Control:

Enables proper imaging for different densities and thicknesses in industrial or medical applications.

-

Radiation Safety:

Minimizes unnecessary exposure by maintaining optimal voltage levels.

-

Energy Efficiency:

Reduces power wastage while ensuring sufficient X-ray output.

Understanding the correct X-ray voltage is critical for both system designers and operators to achieve accurate, reliable imaging.

High Voltage Generators for X-Ray Systems

A high voltage generator X-ray is the device that produces the high voltage required by the X-ray tube to operate. These generators convert low-voltage electrical input into the tens or hundreds of kilovolts needed to accelerate electrons within the tube. High voltage generators are carefully engineered to maintain stability, precision, and safety, forming the backbone of every advanced X-ray system.

Key aspects of high voltage generators include:

- Voltage Regulation: Ensures the applied voltage remains constant for consistent X-ray production.

- Current Control: Balances the electron flow to maintain optimal tube performance.

- Safety Features: Includes insulation, grounding, and automatic shutdown mechanisms to prevent accidents.

- Compact and Modular Designs: Allows for integration in portable or specialized imaging equipment.

High voltage generators work in tandem with the X-ray tube power supply and control systems, ensuring reliable operation for medical imaging, industrial inspections, and research applications.

Applications of X-Ray Tube Power Supplies, Voltage Control, and High Voltage Generators

The combination of X-ray tube power supplies, precise X-ray voltage, and high voltage generators enables a wide range of applications across multiple industries:

- Medical Imaging:

Modern CT scanners, dental X-ray machines, and portable imaging units rely on precise voltage control and reliable power supply to produce clear and accurate diagnostic images.

- Industrial Non-Destructive Testing (NDT):

High-voltage X-ray generators allow inspectors to examine metal components, welds, and aerospace parts for defects without damaging the material.

- Scientific Research:

Laboratories use X-ray systems for material analysis, crystallography, and semiconductor inspection, all of which require stable and adjustable X-ray voltage.

- Security and Safety Screening:

Airports, cargo screening facilities, and border control systems depend on high-voltage X-ray generators and stable power supplies to detect concealed items accurately and safely.

These applications highlight the importance of each component working in harmony to achieve consistent, reliable results.

Choosing the Right Components for X-Ray Systems

Selecting the right X-ray tube power supply, high voltage generator X-ray, and voltage control system is critical for system efficiency, reliability, and safety. Key considerations include:

- Technical Expertise of the Supplier: Companies with extensive experience in high-voltage X-ray technology provide more reliable and advanced solutions.

- Customizability: Components should be adaptable to meet the specific needs of medical, industrial, or research applications.

- Safety Standards Compliance: Ensure that power supplies and generators meet international safety and performance standards.

- Durability and Maintenance: High-quality components reduce downtime and maintenance costs while extending system lifespan.

- Integration Support: Suppliers should offer technical guidance for seamless integration into complex X-ray systems.

By carefully selecting components, system designers can maximize imaging quality, minimize operational risks, and achieve long-term reliability.

Future Trends in X-Ray Power and Voltage Technology

The field of X-ray technology continues to evolve, with innovations focusing on:

-

Miniaturization of Components:

Smaller, lighter power supplies and generators allow portable and compact systems.

-

Energy Efficiency:

Advanced designs reduce power consumption while maintaining performance.

-

Enhanced Voltage Control:

Digital and automated systems provide finer control for improved image quality.

-

Integration with AI and Smart Systems:

Smart power management enhances diagnostics and inspection efficiency.

-

Improved Safety Mechanisms:

Advanced insulation, monitoring, and shutdown systems reduce operational hazards.

These trends ensure that X-ray systems become more versatile, reliable, and capable of meeting growing industrial, medical, and research demands.

Conclusion

Advanced X-ray tube power supplies, precise X-ray voltage control, and high-performance high voltage generators for X-ray systems form the backbone of modern imaging, non-destructive testing (NDT), and diagnostic applications. These critical components ensure X-ray systems operate safely, efficiently, and reliably, delivering accurate and consistent imaging even in the most demanding industrial, medical, and scientific environments. By leveraging cutting-edge design, rigorous quality standards, and innovative engineering, manufacturers and suppliers enable OEMs and system integrators to develop next-generation X-ray solutions that meet complex performance requirements.

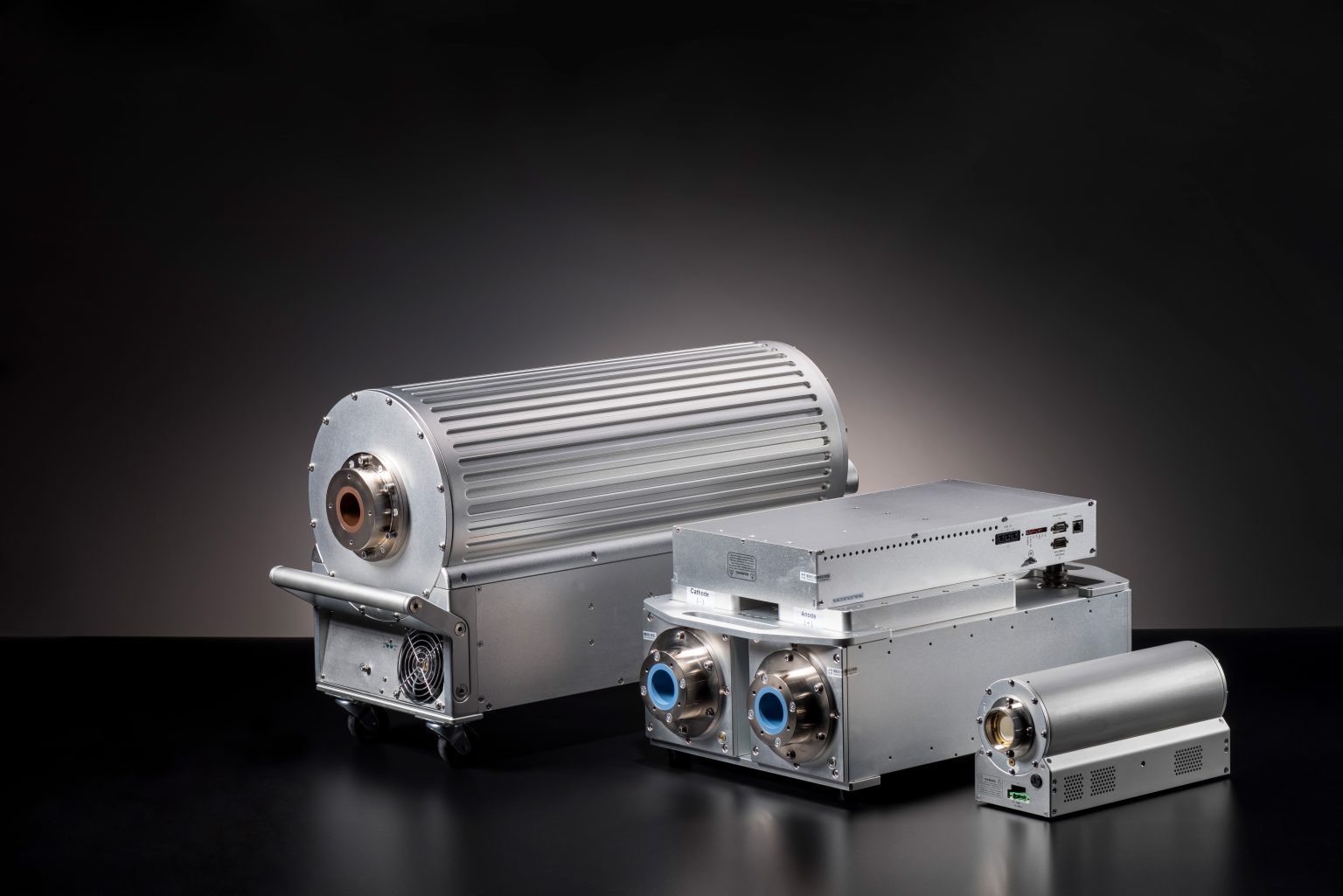

VJ X-Ray continues to set global standards by delivering advanced X-ray tube power supplies, high voltage generators, and precise X-ray voltage solutions. Their components ensure OEM partners worldwide can achieve safe, efficient, and high-performance X-ray applications across medical, industrial, and scientific fields, making X-ray technology an indispensable tool for innovation and critical applications across industries.