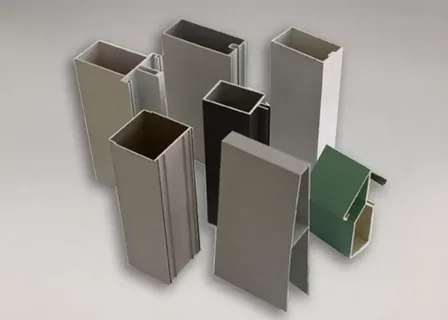

Modern infrastructure and product manufacturing increasingly depend on Powder Coated Aluminium Profiles to achieve durability, visual consistency, and long term operational value. These profiles combine the inherent advantages of aluminium with a robust surface finish that protects against environmental exposure and mechanical wear. Architects, engineers, and fabricators rely on such solutions to balance performance with aesthetics across diverse applications. As industries move toward sustainable and efficient materials, aluminium continues to stand out due to its recyclability and adaptability. The idea of Aluminium Extrusion Made easy reflects how refined processes now simplify production while maintaining strict quality expectations.

Aluminium as a versatile engineering material

Aluminium is valued for its lightweight nature and impressive strength to weight ratio. These properties allow structural efficiency without adding unnecessary load. The metal naturally resists corrosion through the formation of an oxide layer, making it suitable for indoor and outdoor use. Extrusion enables aluminium to be shaped into complex cross sections that meet precise dimensional requirements. This flexibility supports innovative designs while maintaining consistency. When paired with Powder Coated Aluminium Profiles, the base material gains additional protection and enhanced visual appeal for demanding environments.

Importance of surface protection

Surface protection is essential to preserve aluminium performance over extended service periods. Exposure to moisture, pollutants, and ultraviolet radiation can gradually affect untreated surfaces. A protective coating acts as a barrier that minimizes wear and surface degradation. Powder coating provides a uniform finish that adheres strongly to aluminium substrates. This approach improves resistance to scratches and impacts. The combination of extrusion accuracy and coating reliability ensures finished components meet functional and aesthetic expectations.

Overview of the powder coating process

The powder coating process involves applying finely ground particles to a prepared aluminium surface using electrostatic attraction. Once applied, the coated material is cured in a temperature controlled oven. During curing, the powder melts and forms a smooth, continuous film. This method avoids the use of liquid solvents, reducing emissions and waste. The result is a durable and consistent finish. Through this process, Powder Coated Aluminium Profiles achieve high performance standards suitable for critical applications.

Durability and resistance benefits

Durability is a defining advantage of powder coated finishes. The cured layer resists chipping, fading, and abrasion under normal use conditions. It also provides protection against corrosion in humid, coastal, or industrial environments. This resilience extends the lifespan of aluminium components. Reduced deterioration lowers maintenance frequency and costs. As a result, Powder Coated Aluminium Profiles deliver dependable performance across long project timelines.

Design flexibility and finish options

Design flexibility is another key benefit of powder coating. Manufacturers can offer a wide selection of colors, textures, and gloss levels. Finishes may replicate wood grain, metallic effects, or contemporary matte appearances. This versatility allows designers to achieve visual harmony without sacrificing structural performance. Color consistency across batches supports uniform aesthetics in large developments. With Powder Coated Aluminium Profiles, creative freedom aligns with technical reliability.

Environmental and sustainability considerations

Powder coating supports environmentally responsible manufacturing practices. The process produces minimal volatile organic compounds, contributing to improved air quality. Overspray can often be recovered and reused, reducing material waste. Aluminium itself is highly recyclable, retaining value through repeated reuse cycles. These attributes support sustainable construction and manufacturing goals. Choosing Powder Coated Aluminium Profiles aligns with modern environmental compliance expectations.

Quality control and performance testing

Maintaining consistent quality requires structured inspection and testing protocols. Surface preparation is evaluated to ensure proper coating adhesion. Coating thickness measurements confirm uniform coverage. Samples may undergo impact resistance and weather simulation tests. These checks verify performance under expected service conditions. Robust quality systems ensure Powder Coated Aluminium Profiles meet established standards and customer specifications.

Applications across construction and industry

Powder coated aluminium components are used widely across sectors. In construction, they support windows, doors, façades, and curtain wall systems. Transportation industries utilize them for lightweight structural elements. Electrical enclosures and support frames benefit from their insulating and protective properties. Furniture, signage, and renewable energy installations also rely on Powder Coated Aluminium Profiles for durability and appearance.

Ease of handling and installation

Lightweight aluminium simplifies transportation and on site handling. The protective coating reduces surface damage during installation. Precision extrusion allows tight tolerances that support accurate alignment. Faster installation reduces labor requirements and project timelines. These efficiencies make Powder Coated Aluminium Profiles suitable for large scale developments with strict schedules.

Economic value and cost efficiency

Economic considerations play a major role in material selection. While initial costs vary based on specification, long service life improves overall return. Reduced maintenance and replacement needs lower operational expenses. Standardized production supports cost effective supply for bulk orders. These factors make Powder Coated Aluminium Profiles an attractive choice for budget conscious projects.

Role of technology and innovation

Technological advancements continue to improve aluminium finishing outcomes. Automated systems enhance precision and repeatability. Improved coating formulations increase weather resistance and color retention. Digital monitoring supports consistent curing conditions. Innovation also enables faster turnaround times. Through these improvements, Powder Coated Aluminium Profiles evolve to meet changing market needs.

Future industry outlook

Global demand for durable and sustainable materials continues to grow. Urban expansion and infrastructure investment drive aluminium usage. Designers seek materials that balance performance with appearance. Ongoing research will further refine coating efficiency. These trends indicate sustained relevance for Powder Coated Aluminium Profiles in future projects.

Key selection considerations

• Structural requirements should align with profile design.

• Environmental exposure influences coating specification.

• Dimensional accuracy supports seamless integration.

• Regulatory compliance ensures safety and approval.

• Custom lengths reduce on site modifications.

Conclusion

Powder Coated Aluminium Profiles represent a reliable and efficient solution for modern construction and industrial requirements. Their combination of lightweight strength, corrosion resistance, and enhanced surface durability makes them suitable for a wide range of environments and applications. The powder coating process adds long lasting protection while maintaining consistent visual quality, which supports both functional performance and design expectations. With low maintenance needs and strong resistance to weathering, these profiles help extend service life and reduce long term operational costs.

Powder Coated Aluminium Profiles offer a balanced combination of strength, durability, design flexibility, and sustainability. Their protective finishes enhance performance across diverse environments while reducing maintenance demands. Through quality control, innovation, and proper installation, these solutions deliver long term value. For dependable supply and expert support, JM Aluminium provides high quality aluminium solutions tailored to project needs and has made Aluminium Extrusion Made easy. Partnering with JM Aluminium ensures reliable performance, consistent finishes, and trusted service for future focused developments.